Composite material repair in automotive applications involves early identification of damage like cracks and delaminations through advanced inspection tools. Non-Destructive Testing (NDT) techniques such as ultrasonic testing and radiography assess structural integrity without harming materials. Repair strategies include bonding with strong adhesives, replacement with new composite materials, and advanced replication of complex shapes, ensuring structural integrity, aesthetic appeal, and compliance with safety standards for efficient, cost-effective, and durable solutions.

Composite material repair techniques are transforming automotive industry standards. With increasing composite material usage in vehicle construction, understanding and addressing damage effectively is crucial. This article delves into the intricacies of composite material repair for vehicles, covering everything from recognizing damage to advanced bonding and replacement strategies. By exploring non-destructive testing methods, professionals can ensure accurate assessments and precise repairs, maintaining structural integrity and performance.

- Understanding Composite Material Damage in Vehicles

- Non-Destructive Testing Methods for Repair Assessment

- Advanced Repair Techniques: Bonding and Replacement Strategies

Understanding Composite Material Damage in Vehicles

Understanding Composite Material Damage in Vehicles

Composite materials, known for their strength and lightweight properties, are increasingly used in automotive manufacturing, particularly in car bodies and components. However, like any material, composites can sustain damage over time due to various factors such as impact, exposure to harsh weather conditions, or normal wear and tear. Identifying composite material damage early is crucial for maintaining vehicle integrity and performance. Cracks, delaminations, and fiber breaks are common types of damage that require prompt attention during car repair shop visits.

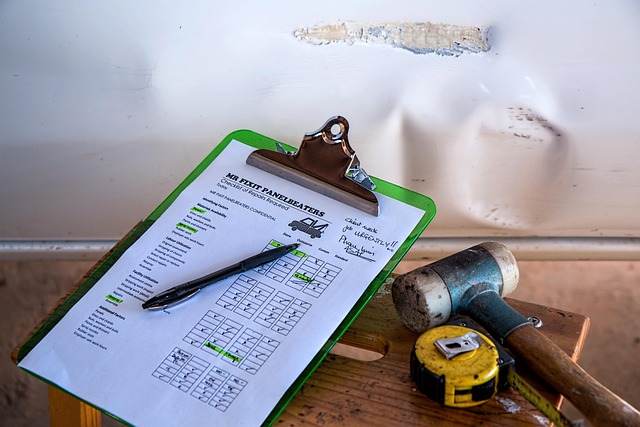

automotive repair services focusing on composite material repair must employ specialized techniques to effectively address these issues. This often involves meticulous inspection using advanced tools and technologies to pinpoint the extent of the damage. Once identified, auto body services may include patching, bonding, or even complete replacement of affected areas to restore the structural integrity and aesthetic appeal of the vehicle. Proper composite material repair ensures not only the safety and reliability of the vehicle but also preserves its value in the long run.

Non-Destructive Testing Methods for Repair Assessment

Non-Destructive Testing (NDT) methods play a pivotal role in assessing composite material repairs for automotive applications. These techniques allow technicians to evaluate damage and structural integrity without causing further harm to the material. NDT is particularly crucial when dealing with advanced composite materials, which are widely used in modern vehicle construction due to their lightweight nature and superior strength-to-weight ratios. Common NDT methods include ultrasonic testing, magnetic particle inspection (MPI), and radiographic examination, each offering unique advantages for specific types of damage, such as cracks, voids, or delaminations.

By employing these non-invasive techniques, repair specialists can accurately determine the extent of damage, guide appropriate repair strategies, and ensure that composite components meet safety standards. This is especially vital in fleet repair services where efficient, cost-effective solutions are sought to maintain vehicle performance and longevity, including effective dent removal and meticulous car paint repair processes.

Advanced Repair Techniques: Bonding and Replacement Strategies

Advanced composite material repair techniques have revolutionized car repair shops, offering efficient and durable solutions for car body repair and restoration. Bonding is a sophisticated method where a strong adhesive is used to fuse damaged composite components back together, ensuring a seamless integration that matches the original quality. This process demands precision and expertise to maintain the structural integrity of the vehicle.

Replacement strategies take a different approach, involving the use of new composite materials to outrightly substitute damaged or deteriorated parts. This method ensures not just repair but also upgrades the overall strength and aesthetics of the car body. With advancements in technology, these strategies have become more precise, allowing for complex shapes and designs to be replicated, thereby enhancing the overall look and performance of the vehicle in car restoration processes.

Composite material repair techniques have revolutionized automotive industry standards, offering efficient solutions for damage assessment and restoration. By employing non-destructive testing methods and advanced bonding strategies, professionals can ensure structural integrity and aesthetic appeal in vehicle repairs. These innovative approaches not only enhance the durability of composites but also contribute to more sustainable automotive practices, making composite material repair an indispensable skill for modern car care.