Composite materials have dramatically improved sports cars' performance, but their intricate structure presents unique challenges for repairs. Specialized auto body services are crucial for restoring these cars' structural integrity and aesthetic appeal after accidents or wear and tear. Advanced techniques like automated fiber placement (AFP) and 3D printing, coupled with precise paint repair methods, ensure these high-performance vehicles maintain their lightweight designs, durability, and vibrant appearances, showcasing the expertise required in composite material repair.

In the realm of high-performance sports cars, composite materials have revolutionized design, offering unparalleled strength-to-weight ratios. However, their intricate structures present unique challenges during repairs, demanding precision and advanced techniques. This article explores the intricacies of composite material repair for these elite vehicles. We delve into the significance of composites, uncover common repair hurdles, and highlight cutting-edge technologies ensuring effective restoration while maintaining peak performance. Discover the game-changing approaches transforming composite repair in the automotive industry.

- Understanding Composite Materials and Their Significance in Sports Cars

- Challenges of Composite Material Repair for High-Performance Vehicles

- Advanced Techniques and Technologies for Effective Composite Repair

Understanding Composite Materials and Their Significance in Sports Cars

Composite materials have revolutionized the automotive industry, especially in high-performance sports cars. These advanced materials offer exceptional strength-to-weight ratios, enabling manufacturers to create lighter and faster vehicles. In sports cars, where every gram counts, composite material repair is an art that ensures these vehicles maintain their optimal performance and structural integrity. When damage occurs due to accidents or regular wear and tear, auto body services specializing in composite material repair become indispensable.

The significance of composite materials in sports cars extends beyond their weight-saving benefits. They provide superior durability, corrosion resistance, and dimensional stability, all crucial factors for vehicles designed to reach extraordinary speeds. With proper care and expert repairs, these materials can restore a damaged sports car’s structural integrity, ensuring it performs as seamlessly as the day it rolled off the assembly line. This specialized auto body repair process involves intricate techniques to match the composite material’s properties, offering not just a visual fix but also a reliable solution for vehicle dent repair and even complex auto frame repair tasks.

Challenges of Composite Material Repair for High-Performance Vehicles

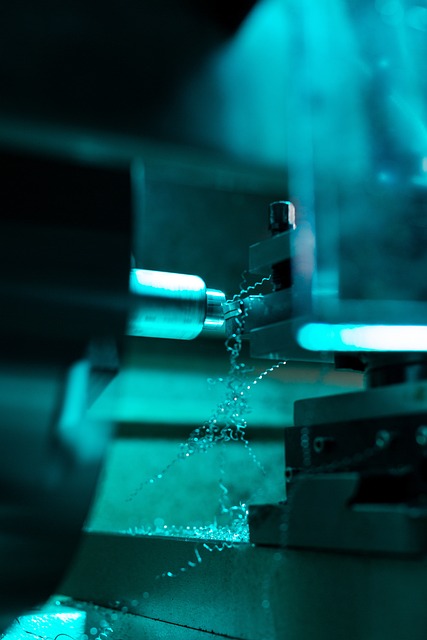

The use of composite materials in high-performance sports cars brings both benefits and unique challenges when it comes to repair. One of the primary difficulties lies in the intricate nature of these materials, which often consist of layers of fiber reinforced polymers. Damage, such as car dent repair or even minor cracks, can be complex to assess and fix accurately. Composite material repair requires specialized tools and techniques, unlike traditional car scratch repair methods, demanding a higher level of expertise from auto repair shops.

Additionally, the structural integrity of composite components is critical for vehicle performance. Repairs must not only address the visible damage but also ensure the overall strength and stability of the affected areas. This precision work necessitates a deep understanding of composite material properties and advanced repair techniques, often involving specialized training and equipment, setting it apart from conventional auto repair processes.

Advanced Techniques and Technologies for Effective Composite Repair

In the realm of high-performance sports cars, where precision and speed reign supreme, composite material repair has emerged as a game-changer. Advanced techniques like automated fiber placement (AFP) and 3D printing allow for the creation of complex geometries, ensuring structural integrity while maintaining the vehicle’s lightweight design – crucial factors for optimal performance. These innovative technologies enable auto body shops to accurately replicate original factory components, addressing damage from automotive collision repair with meticulous detail.

Moreover, modern composite material repair encompasses not just structural fixes but also aesthetic enhancements. Advanced techniques in vehicle paint repair, including robotic spraying and computer-aided color matching, ensure that the final product is a perfect fusion of form and function. This level of precision is vital for maintaining the car’s vibrant, bustling appearance, making it a true testament to the owner’s dedication to high-performance driving.

The future of high-performance sports car manufacturing lies in the innovative use of composite materials, which offer unparalleled strength-to-weight ratios. However, the intricate nature of these structures presents unique challenges during repairs, requiring advanced techniques and technologies. By embracing modern composite material repair methods, manufacturers can ensure the structural integrity and optimal performance of these powerful machines while minimizing downtime. This ensures that high-performance sports cars continue to deliver exceptional driving experiences.