Composite material repair involves addressing damage like cracks and delaminations caused by impacts or minor incidents. Vacuum bagging is a key technique where air and moisture are removed from the damaged area through a sealed vacuum bag to facilitate resin infusion, enhancing bonding and laminating for precise, durable repairs that match structural integrity and aesthetic appeal of original vehicles, as demonstrated by Mercedes Benz specialists.

“Discover efficient composite material repair techniques with vacuum bagging, a game-changer in advanced manufacturing. This comprehensive guide delves into the intricate world of composite material damage assessment and offers a step-by-step exploration of the vacuum bagging process. Learn how this method enhances repair precision and strength. From understanding damage types to implementing best practices, you’ll find everything needed to master composite material repair techniques, ensuring superior results.”

- Understanding Composite Material Damage

- Vacuum Bagging: A Comprehensive Guide

- Repair Process and Best Practices

Understanding Composite Material Damage

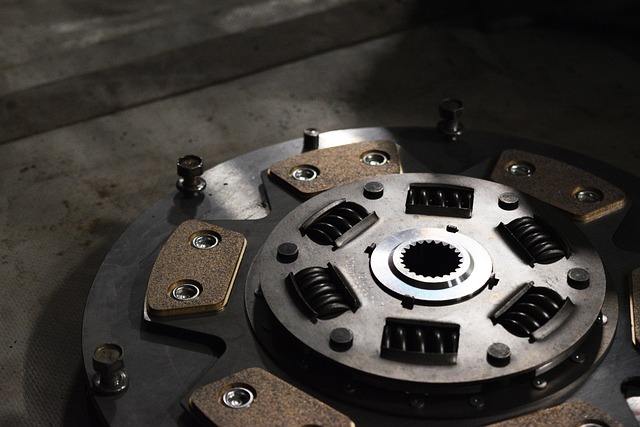

Composite materials, while renowned for their strength and lightweight properties, are susceptible to various forms of damage, especially in automotive applications. Understanding these damages is the first step in effective composite material repair. Cracks, delaminations, and fiber breaks are common issues that can arise due to impact events, such as car accidents or exposure to extreme conditions. Even seemingly minor incidents like car scratches or dents can compromise the structural integrity of composite components if left unattended.

Proper assessment is crucial for determining the extent of the damage. Visual inspection often reveals visible cracks or deformities, while more subtle issues like delaminations might require advanced diagnostic tools. In body shop services, technicians employ various techniques to assess and repair these damages, including vacuum bagging as a composite material repair method. This process involves sealing the damaged area with a vacuum bag, creating controlled pressure that aids in resin infusion or de-gassing during the repair process, ensuring optimal composite material restoration akin to car dent removal or scratch repair.

Vacuum Bagging: A Comprehensive Guide

Vacuum bagging is a specialized technique employed in composite material repair, offering a controlled and efficient environment for bonding and laminating. This process involves sealing a damaged area with a flexible vacuum bag, creating a vacuum between the bag and the surface, which removes air and moisture from the joint. By eliminating these elements, the adhesion between the repair materials and the existing composite is significantly enhanced.

The method is particularly effective in auto body services where complex shapes and intricate designs require precise repairs. It’s an ideal solution for scratch repair or more significant damage, ensuring a strong and durable fix. Auto body shops utilizing vacuum bagging can achieve superior results in their composite material repair processes, providing customers with high-quality, long-lasting solutions for their vehicles’ structural integrity and aesthetic appeal.

Repair Process and Best Practices

The composite material repair process involves a meticulous approach to ensure the structural integrity and aesthetic quality of the final restoration. It begins with careful inspection to identify the extent of damage, followed by preparation of the affected area. This includes cleaning, degreasing, and ensuring the surface is free from any contaminants that could hinder bonding. The next step is to apply an appropriate primer to create a strong bond between the repair material and the composite surface. This is crucial for the longevity of the repair.

Best practices in composite material repair emphasize precision and attention to detail. Vacuum bagging is a technique often employed, where a vacuum-tight bag is used to enclose the repair area, creating an airtight environment. This process ensures precise application of resin and hardener, facilitating better control over the curing process. For instance, Mercedes Benz collision repair specialists leverage this method for bumper repair, achieving excellent results. Collision repair services that employ such techniques offer superior repairs, ensuring the restored vehicle looks as good as new, with enhanced structural strength.

Composite material repair using vacuum bagging offers a versatile and effective solution for damaged components. By understanding the nature of composite damage and mastering the vacuum bagging technique, technicians can ensure robust repairs that maintain structural integrity and performance. This method, coupled with best practices, enables efficient restoration of composite materials, making it an indispensable tool in the aviation, automotive, and maritime industries for cost-effective and reliable composite material repair.